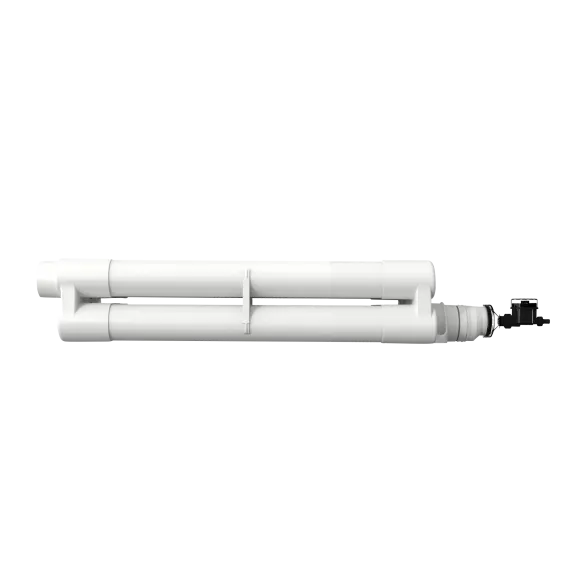

First Flush Delta In-Ground

A high volume first flush diverter, designed specifically for inground applications. Divert the dirtiest water and transform your rain harvesting system from “wet” to “dry” with this large volume inground first flush diverter.

The unique manifold design uses standard 100mm or 4" pipe to create a high capacity storage and diversion chamber for your first flush. Using these smaller pipe sizes makes it easier to source pipe and assemble the system, when compared to using large diameter pipe on traditional high volume diverters.

Divert Large volumes of water, easily

Ultimate First Flush control

Easy Maintenance

Just add pipe

Benefits

Divert Large volumes of water, easily

Standard large format First Flush Diverters require you to use large diameter pipe (eg, 300mm / 12"). It can be difficult to source in smaller lengths and can be expensive.

The Delta's unique manifold design uses lengths of 100mm or 4" pipe instead, so sourcing the pipe to make the chamber is easier. It means you can assemble your First Flush Diverter quicker, to get the job done.

Each 1 meter of length in the Delta = 73 L diversion.

Each 1 yard of length in the Delta = 17.5 gal diversion.

Benefits

Ultimate First Flush control

By setting the regularity of your first flush diversion, you can optimise how often your First Flush Diverter drains.

Do you want the best quality water possible? Set it to a regular reset interval of three days or less.

Do you need to maximise the volume of water your capture? Increase the reset interval to two weeks or more.

Want to start off with a great compromise of water quality and quantity? Try five days.

Benefits

Just add pipe and your T-Piece

This First Flush Delta In-Ground comes with most fittings you need to set the system up. Just your own T-piece according to your setup and add the pipe to create the storage chamber.

Benefits

Prevent anaerobic fermentation

In-Ground diverters periodically drain the water-filled pipes in your “wet” rain harvesting system to prevent anaerobic fermentation and stop fermented water contaminating the rainwater in your tank. This drained water can then be released or used to water your garden.

Benefits

Less maintenance and clogging

Traditional First Flush Diverter valves have a tendency to clog over time - they only have a tiny hole so it is inevitable. The release valve on the Delta First Flush includes a unique funnel design and a much larger draining hole, which means that water drains as it's supposed to and there is far less chance of the unit becoming clogged.

Benefits

Divert Large volumes of water, easily

Standard large format First Flush Diverters require you to use large diameter pipe (eg, 300mm / 12"). It can be difficult to source in smaller lengths and can be expensive.

The Delta's unique manifold design uses lengths of 100mm or 4" pipe instead, so sourcing the pipe to make the chamber is easier. It means you can assemble your First Flush Diverter quicker, to get the job done.

Each 1 meter of length in the Delta = 73 L diversion.

Each 1 yard of length in the Delta = 17.5 gal diversion.

Benefits

Ultimate First Flush control

By setting the regularity of your first flush diversion, you can optimise how often your First Flush Diverter drains.

Do you want the best quality water possible? Set it to a regular reset interval of three days or less.

Do you need to maximise the volume of water your capture? Increase the reset interval to two weeks or more.

Want to start off with a great compromise of water quality and quantity? Try five days.

Benefits

Just add pipe and your T-Piece

This First Flush Delta In-Ground comes with most fittings you need to set the system up. Just your own T-piece according to your setup and add the pipe to create the storage chamber.

Benefits

Prevent anaerobic fermentation

In-Ground diverters periodically drain the water-filled pipes in your “wet” rain harvesting system to prevent anaerobic fermentation and stop fermented water contaminating the rainwater in your tank. This drained water can then be released or used to water your garden.

Benefits

Less maintenance and clogging

Traditional First Flush Diverter valves have a tendency to clog over time - they only have a tiny hole so it is inevitable. The release valve on the Delta First Flush includes a unique funnel design and a much larger draining hole, which means that water drains as it's supposed to and there is far less chance of the unit becoming clogged.

Product Installation, Maintenance and Information

Specifications

All measurements are in mm unless specified otherwise

Click the drawing to view it in full size

Pipe Fitment

You may also like

We’re sorry, the product you are looking for is not available in this region. Click here to view all available products for this region.

If you need help, please contact our team who will be glad to assist.

Looking for something else?

View the full product range from our home base in Australia.

First Flush Calculator

Easily calculate how much water you need to divert and discover which First Flush Diverter is right for you.

Design Service

Improve your existing Rain Harvesting system or design a new one with the help of our experts and our free system design service.

Rain Harvesting Handbook

A guide that will provide you with help and inspiration to start your rainwater harvesting journey today.

Design Service

Improve your existing Rain Harvesting system or design a new one with the help of our experts and our free system design service.